Welcome to the JeepSpecs.com in-depth page of WJ Generation Jeep Grand Cherokee trim and components. Did we mis anything? Please get in touch with us and tell us about it!

The liftgate trim panel is attached with 5 screws, 4 spring clips and 10 plastic fasteners

Trim panel removal

1. Raise the liftgate

2. Remove the 5 phillips screws securing the liftgate trim panel to the liftgate

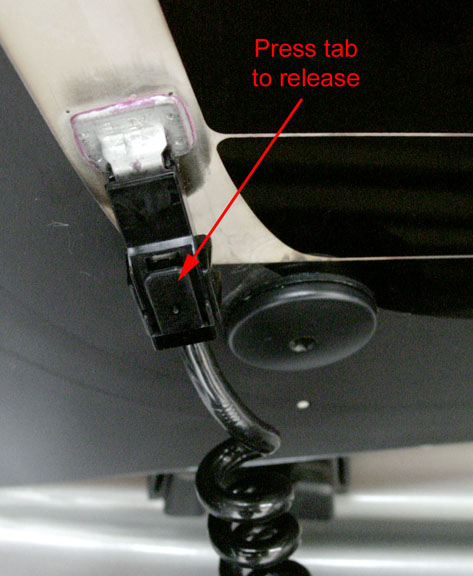

3. Disconnect both rear window defroster wires, which are locked into place (See photo below).

4. Using a trim stick or equivalent, carefully pry the liftgate trim panel off the liftgate. There are 10 plastic fasteners used on the liftgate, with 3 different sizes used. These break easily so it is a good idea to have a few spares on hand.

5. To access the interior components, remove the black insulator cover from the liftgate. This is attached with a light adhesive and can slowly be pulled off.

Defrost connectors: Press the tab on the connector to release it and carefully wiggle the connector out. Keep it parallel to the glass, do not bend it up or down.

The black vinyl insulator cover is attached with a mild adhesive

Reinstalling the trim panel

1. Inspect all 10 of the plastic fasteners, making sure they are locked in place and straight, and that they are not broken or damaged.

2. If you have removed the black insulator pad, reinstall it, working from one side to the other, making sure that the cut-out holes are aligned properly. Take a small towel and rub around the edges to nicely seal it back in place.

3. With the liftgate fully open, lift the trim piece and hold in the approximate position up against the liftgate. Start by aligning the two yellow bottom fasteners into their holes, once both are lined up, hit the trim with your palm in the area directly above each fastener to lock them firmly in place. Next, align the next two plastic fasteners on one side, and then the other side, and snap them into place. You should now have all 6 lower connectors fastened.

4. At the top portion of the trim piece, check that the coiled defroster wires are routed through their slots that are cut in to the top of the trim panel.

5. Align each of the 4 top white fasteners, starting them in their holes and lightly holding the trim panel in place to keep them from slipping out. Also make sure the 4 spring clips are lined up as well. When everything is lined up, tap each area above the fastener firmly with your palm to seat them into place.

6. Check the entire perimiter of the trim panel to make sure it is seated flat against the liftgate. Install the 3 short lower phillips screws. Close the liftgate and open the liftgate window. This will allow easier access to line up the two long screws that are by the window latch. You may have to pull the trim towards you a little and move it as sometimes the screws are tough to align in their holes.

7. Carefully reconnect the two defroster wires, making sure they “lock” into place.

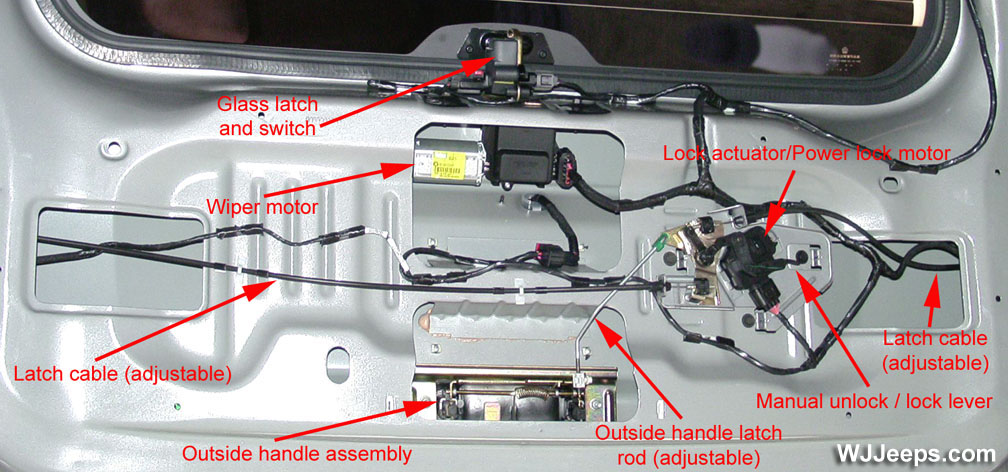

Liftgate interior components

Liftgate cable and latch adjustments

Latch adjustment:

(1) With the liftgate closed, slowly open the liftgate using the outside handle.

(2) Determine if excessive handle travel is required to unlatch the liftgate. If so, adjustment to the latch rod may be required.

(3) Open the plastic latch rod retention clip on the outside handle and disconnect the latch rod from the outside handle.

(4) Verify that the latch control assembly is in its fully returned position.

NOTE: Do not pre-load the latch rod when attaching.

(5) Attach the threaded end of the latch rod to the open retention clip. Make sure all excess play has been removed between the outside liftgate handle and the latch assembly.

(6) Fully close the plastic retention clip.

(7) Cycle the outside handle and verify smooth operation.

Cable adjustment:

(1) Determine if one of more of the following occurs:

– Excessive handle travel is required to unlatch the liftgate.

– Only one side of the liftgate will unlatch.

– As one side of the liftgate unlatches, more than 2 mm (0.08 in.) of additional outside handle travel is required to unlatch the other side (latches are not synchronized/timed).

NOTE: Do not close the liftgate during the adjustment procedure.

(2) To adjust the latch cables, open the liftgate.

(3) Open the plastic latch rod retention clip on the outside handle and disconnect the latch rod from the outside handle.

(4) Open both latch cable retention clips and remove the threaded end of the cable from each clip.

(5) Verify that the latch control assembly is in its fully returned position.

(6) Verify that both latch cables slide smoothly and do not bind.

NOTE: The latches must be in their fully closed position to properly adjust the latch cables. The following step is necessary to remove excess cable play at the latch end of the cable.

(7) Using a suitable tool, fully latch (close) both liftgate latches.

(9) Remove the excess play from the other latch cable and seat both cable threaded ends into their respective opened retention clips.

NOTE: Apply a small bead of RTV to both open cable retention clips and threaded cable ends to prevent the threaded ends from rotating within the retention clips.

(10) Close both cable retention clips. Verify complete clip closure.

(11) Adjust the outside handle rod (see above section).

(12) While the liftgate is open and the latch control assembly is still uncovered, slowly open the outside latch handle to unlatch both side latches. Verify both latches unlatch.

(13) Cycle the liftgate closed and open to verify correct operation of the liftgate latch system.

Liftgate manual unlock / lock lever

All WJs feature an emergency unlock/lock switch lever for the liftgate. Should the liftgate become locked and unable to be opened due to a switch or circuit failure, a manual unlock/lock lever is accessible behind a small panel on the interior trim panel. As shown in the photos above, the lever can be moved up or down to unlock or lock the liftgate door.

Flip-up glass prop rods

1. Open the liftgate glass

2. Using a trim stick or equivalent, gently pry open the locking cap on the top end of the prop rod

3. Rotate prop downwards to disconnect it from the lower ball stud.

4. Install new cylinder in place

5. Compress locking cap to lock the rod on the ball stud. Lower window slowly to verify proper operation

Liftgate glass support rods

1. Open and support the liftgate. It easiest (and probably safer) to also have a second person help out and support each side of the liftgate as each rod is being changed. Rods should be replaced in pairs.

2. Remove the two T-40 torx screws attaching the rod to the liftgate and vehicle body and remove the rod.

3. Install new support rod and tighten the Torx screws

4. Lower liftgate slowly to verify proper operation

Liftgate related parts |

||

| Item | Part # | MSRP |

| Lock actuator, liftgate | 5018479AB (1999-2004) | $108.10 |

| Wiper motor, rear | 55155122AG (1999-2004) superseded by RL155122AG (1999-2004) |

$117.00 |

| Wiper arm, rear | 5102882AA (1999-2004) | $58.35 |

| Wiper blade, rear | 5102881AB (1999-2004) | $13.50 |

| Prop rod, flip-up glass | 55136965AE (1999 – NOTE: must replace entire glass assembly)55136965AE (2000-2004) | $42.35 (rod only)$43.25 |

| Support rod, liftgate | 55137023AA (left, 1999-2000) 55137022AA (right, 1999-2000)55137023AC (left, 2001-2004) 55137022AC (right, 2001-2004) |

$47.25 $47.25$62.60 $62.60 |

| Weatherstrip, liftgate Glass | 55136053AB (1999)55136053AD (2000)

55363160AD (2001-2004) |

$36.00$37.25

$80.85 |

| Seal, liftgate | 55135388AD (1999-2004) | $115.00 |

| Insulation cover, liftgate | 55136185AC (1999-2004) | $47.85 |

| Trim fastener, plastic (white x 4) |

6503709 | $2.35 |

| Trim fastener, plastic (yellow x 4) |

6502991 | $2.45 |

| Trim fastener, plastic (green x 2) |

6503204 | $7.50 |